- Home

- About

- Blog

-

Products

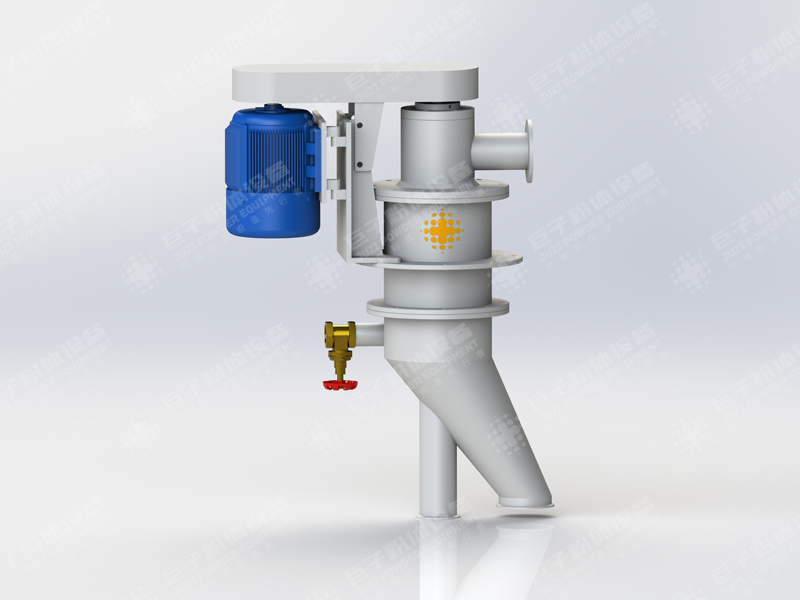

- JZFDB inert gas shielding gas flow classifier

- JZLDB inert gas protection jet mill

- Special powder equipment for laboratory

- JZL fluidized bed jet mill

- JZF high precision turbine air classifier

- JZC graded impact mill

- JZXP rotary jet jet mill

- JZOSP High Efficiency Airflow Classifier

- JZH Ultramicro Ring Mill

- More Products

- Applications

- Case

- Service

- Laboratory

- Contact

Fine chemical industry industry solutions

The fine chemical industry is one of the most dynamic emerging fields in the chemical industry today, and has broad prospects for development. The fine chemical industry, with its technology-intensive, high added value of products, large industrial relevance and rapid demand growth, has become the strategic focus of countries around the world to promote the development of the chemical industry to high-end. In the grinding and crushing, after 30 years of continuous research and exploration of the Sichuan giant has a more advanced technical experience. Through massive test data and equipment on-site use experience, we can solve various material handling problems for customers and provide customized complete system solutions such as superfine grinding, classification, scattering and powder conveying.

Fine chemical industry processing material

Equipment We Can Provide

Advantages of our equipment

Accurate grading

Accurate grading

High fineness of finished product

High fineness of finished product

High efficiency

High efficiency

High yield

High yield

Explosion-proof

Explosion-proof

Automation

Automation

Low noise

Low noise

Environmental protection and no pollution

Environmental protection and no pollution

Special equipment for typical materials

Customer Case

Grinding and Classification of Sichuan Industrial Salt

Grinding and Classification of Petroleum Coke in Inner Mongolia

Jiangxi Polyethylene Airflow Classification

Guizhou Aluminum Hydroxide Crushing

Grinding and Classification of Sichuan Carbon Black

Leshan Diammonia Hydrogen Phosphate Grinding and Classification