- Home

- About

- Blog

-

Products

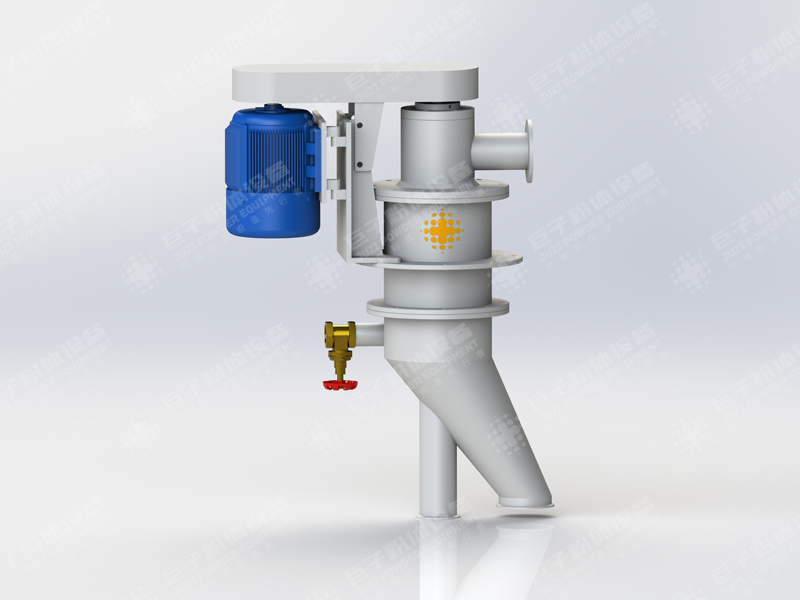

- JZFDB inert gas shielding gas flow classifier

- JZLDB inert gas protection jet mill

- Special powder equipment for laboratory

- JZL fluidized bed jet mill

- JZF high precision turbine air classifier

- JZC graded impact mill

- JZXP rotary jet jet mill

- JZOSP High Efficiency Airflow Classifier

- JZH Ultramicro Ring Mill

- More Products

- Applications

- Case

- Service

- Laboratory

- Contact

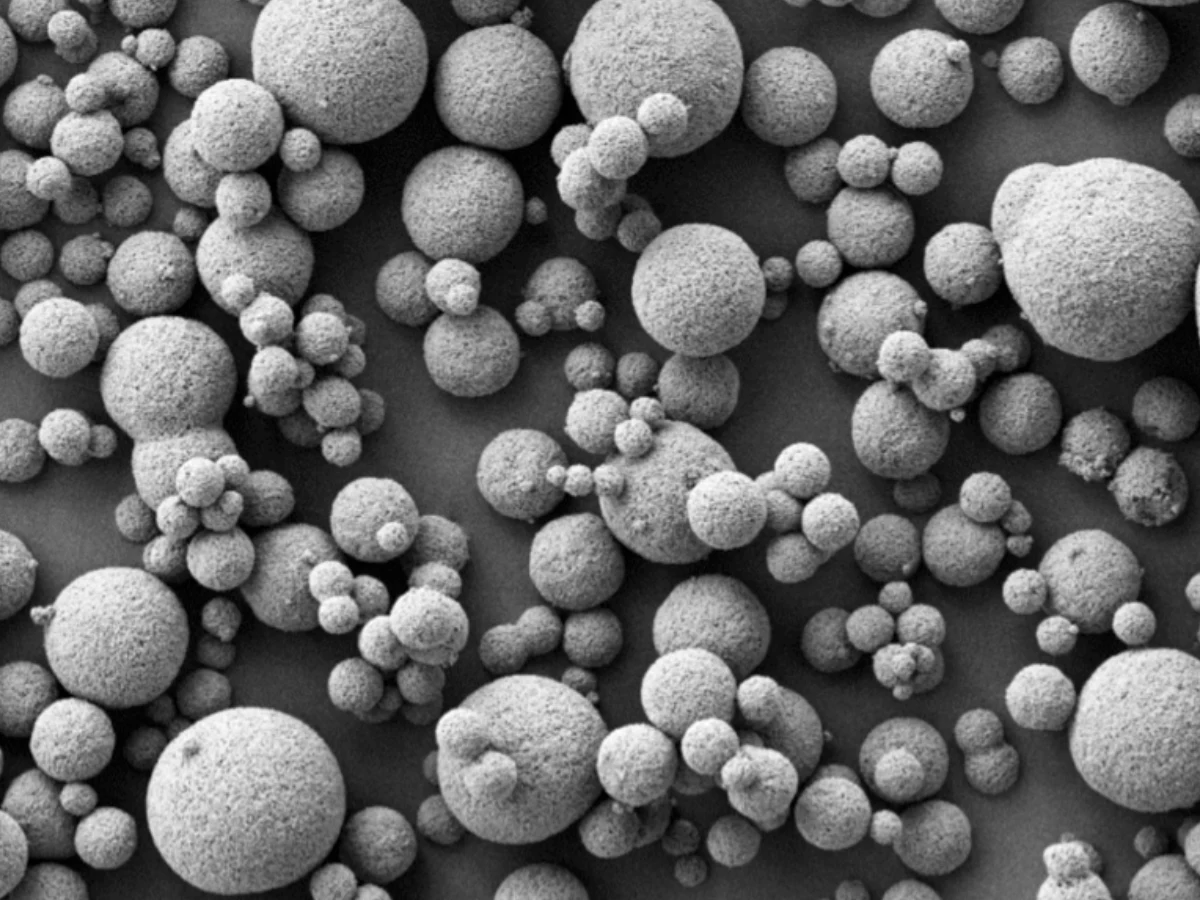

Powder metallurgy industry solutions

With the development of China's industrial modernization, powder metallurgy is widely used in military, aerospace, civil and other fields. Due to the complexity of metallurgical powder production, there are more stringent requirements for enterprises in terms of grinding technology, particle requirements, safety and explosion protection, product purity, oxygen and moisture control and collection system efficiency, and higher screening standards for related equipment and processes.

Powder metallurgy processing material

Equipment We Can Provide

Advantages of our equipment

Accurate grading

Accurate grading

Complete and stable grading flow field and reliable sealing, can carry out precise grading of materials

High fineness of finished product

High fineness of finished product

The finished particle size is arbitrarily adjusted in the range of 1-74 μm.

High purity

High purity

Ceramic parts can be used, zero contact with metal, to ensure the purity of raw materials

Explosion-proof

Explosion-proof

The whole system is provided with explosion-proof holes at different positions of the whole pipeline, so as to minimize the loss in case of bursting and explosion caused by excessive internal pressure and concentration of the system.

Disaggregation

Disaggregation

It has the function of scattering and dispersing the agglomerated material, and improves the fluidity of the powder.

Isolation of oxygen

Isolation of oxygen

Inert gas replaces air to keep the oxygen content in the system basically stable

Constant temperature

Constant temperature

The equipment is equipped with a fin cooler on the pipeline, which can effectively reduce the safety hazards caused by the equipment working for a long time or working in a high temperature environment

Environmental protection and no pollution

Environmental protection and no pollution

Fully enclosed negative pressure operation, dust pollution prevention, excellent and healthy production environment

Special equipment for typical materials

Customer Case

Zhejiang titanium alloy gas flow classification

Jiangsu aluminum alloy scattered classification

Hebei magnesium powder airflow classification